Globaly Serving the Powder Manufacturing Industry

CDM has been designing and manufacturing pharmaceutical material handling and blending equipment for over 32 years. Our primary goal is to provide quality equipment with unmatched customer satisfaction. We will assist you from concept to completion.

Blending Equipment

Setting the new standard in blending with improved design and added flexibilty. Single units capable of blending a variety of blending shell sizes and geometries.

Lifting Equipment

The safest most reliable GMP lifting technology available for all phases of manufacturing including Bins, Drums, Platforms & Bags

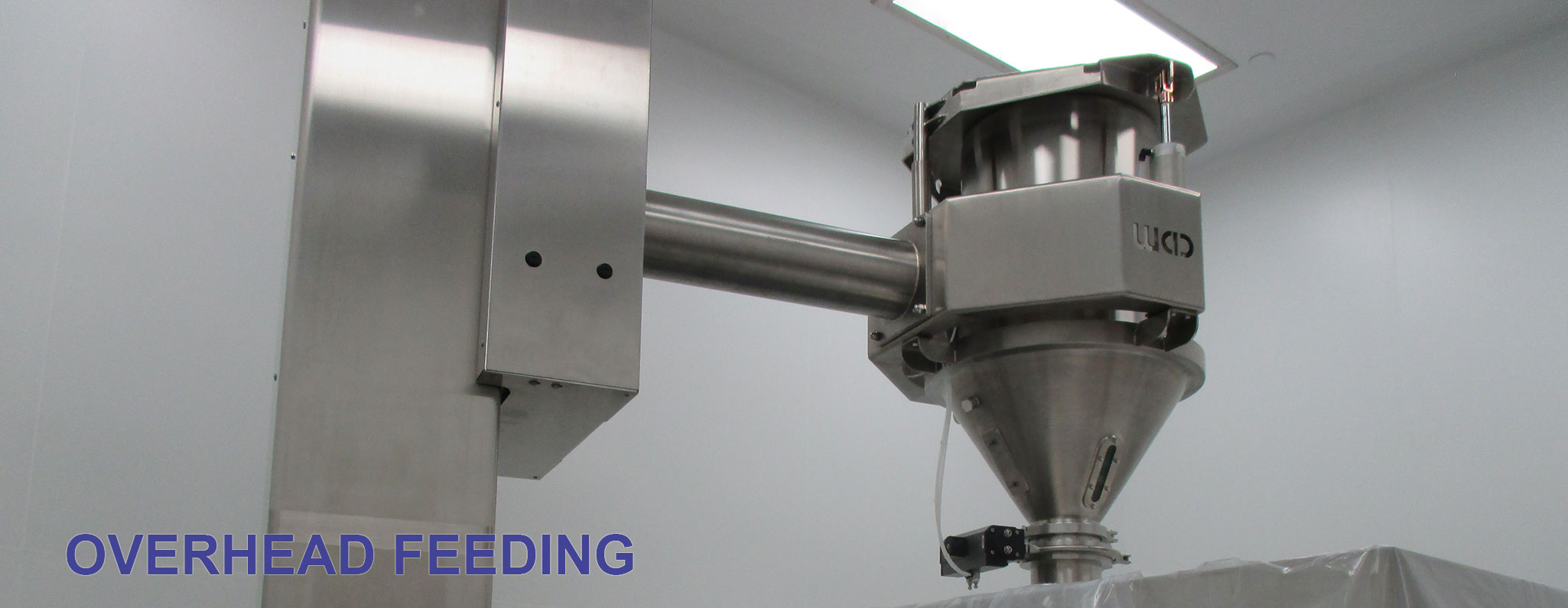

Material Handling

Capable of supplying fully integrated Process Suites to custom fabrication of adapters. Contained handling during Dispensing, Milling/Screening, Blending and Packaging.

Process Layout

Experienced Process Engineers with extensive knowledge for Powder Handling and best practices. Added fabrication services for a single source turn-key provided for new builds or improvements to existing operations.

Seminars & Training

Covering Blending & Material Handling Equipment. This presentation covers the practical approaches for material handling throughout your operation and as it applies to blending and mixing.

Post Blending

Expertise and innovation on Post Blending and Handling. All equipment specifically designed based on the process requirements. Reduce overall handling with improved containment.

Pharma Bag Mfg

TiszaTextil is a renowned supplier of pharmaceutical logistic solutions which can replace cost-intensive investments in cleaning and transport systems.

Controls & Panels

We Offer our customers UL certified general use, industrial machinery, service equipment, and fully integrated process suites. Benefit from the widespread acceptance of the UL Mark by regulatory authorities in every jurisdiction in the United States and Canada..

API Filling Liner

For the safety of the personnel and the protection of the product, the use of continuous liner is very effective and popular. Liner carriers, on the one hand, form the interface between the outlet and the continuous film package, and guarantee otherwise appropriate handling and protection.

API SafeSeal Closure

The manual closure system from Lugaia consisting of clip, crimping and cutting tool, is the affordable solution to seal continuous liners. The user benefits from low investment and maintenance costs. The SafeSeal closure guarantees OEB-Level 5 values in combination with our continuous liner systems and is therefore one of the best manual closure systems.

API Connectors

Tri-Ferrule connectors and process liners available for single use, no cleaning solutions. Cost effective one way version for safe transfer (<1µg pro m3 Containment Level). Cleanroom production according to the state of the art guidelines with USP / EP certificates. Standard versions for Pharmaceutical and Chemistry Version available.

API Transfer

TransferBags meet the high requirements in the pharmaceutical and biotech sector and are responsible for the product transfer of small quantities. Depending on the application, the optimal connectivity and size of the TransferBags is selected.

API Drums

Lower cost of storing and shipping empty packaging. Reduce handling time. Protect your valuable products against moisture, tampering and contamination. Make sure your hazardous solids arrive safely at their destination. Comply with food safety legislation

Clean Pallet Truck

304 or 316 Stainles Steel. 1500Kg & 2000Kg Nominal capacity. 520mm to 680 outside fork width. 85mm to 205mm lift range. Easy and quick lift pump. Single or tandem front wheels. Entry rollers (optional). Unrivalled patented design for easy cleaning.

Electric Scissor Lift

304 or 316 Stainles Steel. 1000Kg Nominal capacity. 540mm to 680 outside fork width. 90mm to 800mm lift range. Electro-Hydraulic Pump. 12 Volt Battery with charger included. Auto height adjustment (optional). Unrivalled patented design for easy cleaning.

Electric Movers

304 or 316 Stainles Steel. 1600Kg, 2000Kg & 2500Kg Nominal capacity. 530mm to 680 outside fork width. 85mm to 205mm lift range. 6km/h Travel Speed. 12 Volt Battery with charger included. Electric Steering (optiona). Cold storage capabilities. Unrivalled patented design for easy cleaning.

PharmaFabric

To improve the competiveness of our customers we use the broad knowledge of their multinational team of specialists in plastics consumer business industries to generate innovation in products and processes.

SafeFlex Isolator

Our isolators are conceptualized, custom made and are suitable for dispensing, sampling and feed processes as well as special applications. The SafeFlex film-material offers a safe protection with high tear resistance and optimum properties for manual handling with tools. After the process, the isolator is closed and can be easily disposed of.

Conductive Bags

A specially designed outer bag exhibits surface resistivity < 10^7ohm, breakdown voltage < 6kV by containing several conductive strings. The contact surface to the goods is a static dissipative multilayer inner bag made in accordance with the latest EU and US pharma requirements.

Transport Frames

Standard and custom designs available to suit the facility requirements. Available in stainless steel with transport and lift provisions. Stacking available for ease-of-storage. Integrated discharge valve to control flow. Capable of collapsing to reduce footprint during storage.

SERVICES

Engineering

Team of Field Technicians and Sales Engineers to review and discuss all aspects onsite as convenient.

Prev Maintenance

Reduce and mitigate equipment down time with routine maintenance and equipment reviews

Controls

UL compliant systems available for new and existing equipment. Programming and IT design consultants available

Design and Fabrication

Complete turnkey equipment and process design to improve existing operations or new layouts. Over 28,000 sq ft of manufacturing and staging facility space. Open invitation to any prospective customers and business partners.

CONTACT US