Globaly Serving the Powder Manufacturing Industry

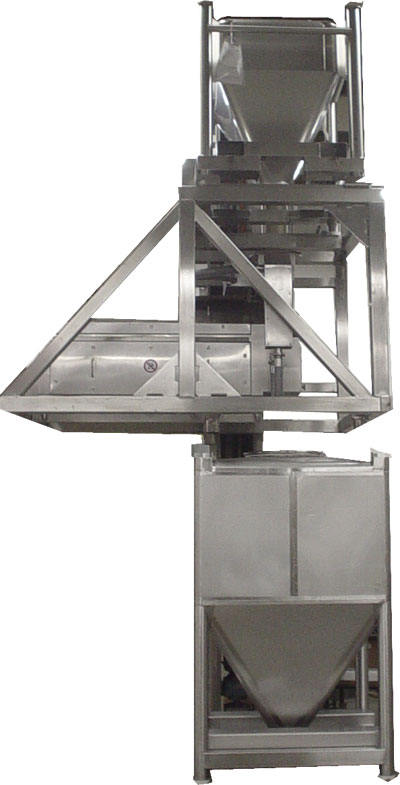

Roller Compactor Lifts

Creative Design and Machine Roller Compactor Lifts sequence is PLC controlled. The lift will be able to lift modules of various sizes. All external components are constructed from 304 stainless steel.

Ball-Screw drive directly coupled to a TEFC brake motor. A ball bearing screw runs on lubricated free moving ball bearings. The screw and nut have matching helical grooves. As the screw or nut rotates, and the rolling balls reach the trailing end of the nut, they are recycled and returned to the leading end of the circuit. The cycle resumes and the balls recirculate continuously. This is the safest and most efficient lifting technology available. The CDM manufactured lift utilizes a directly coupled electrically driven ball-screw with variable frequency drive to assure the most accurate positioning available. Lift/lower speed set at 15 feet/minute. No chains, hydraulics, belts or pulleys are used that can rupture, leak, wear or break.